When a load is raised the forklift is less stable. The Effect of Tyres on Stability.

5 Elements Of Forklift Safety October 2017 Safety Health Magazine

5 Elements Of Forklift Safety October 2017 Safety Health Magazine

Driving with a raised load is dangerous.

A forklift is less stable with a raised load because. It makes the forklift less stable and it can tip over particularly if being driven at speed around a corner or on an uneven surface. Tilting forwards or backwards with a raised load will also affect stability. Lift loads straight up or tilt back slightly.

The truck is less stable with a raised load because. Its recommended to tilt the load back as far as can be done safely. Fork extensions are available to increase fork lift but drivers must be aware that this reduces forklift stability.

Always drive unloaded trucks with the the forks downgrade. When we place an increasing load on the fork tynes the centre of mass of the forklift and load. Should be stationary with the brake applied for all normal lifts.

Maybe less stable with a different shaped load. More important is load height. 1910178o1 Most tipping accidents happen because of the above problems.

It affects the load center and could make the f orklift to tip over. Ramps and Grades module. The rear wheels are slightly elevated.

Lift the load straight up then tilt back slightly. Never drive with the load downgrade. Forklifts tip over more easily and are harder to steer and stop.

Watch that the load doesnt catch on adjacent loads or obstructions. When a load is raised the lift truck is less stable. Only a trained and authorized operator can drive a forklift.

Do not raise or lower the fork unless the lift truck is stopped and braked. Always be aware of the forklifts maximum load capacity prior to operation by checking its data plate. In actual fact the stability triangle is a pyramid.

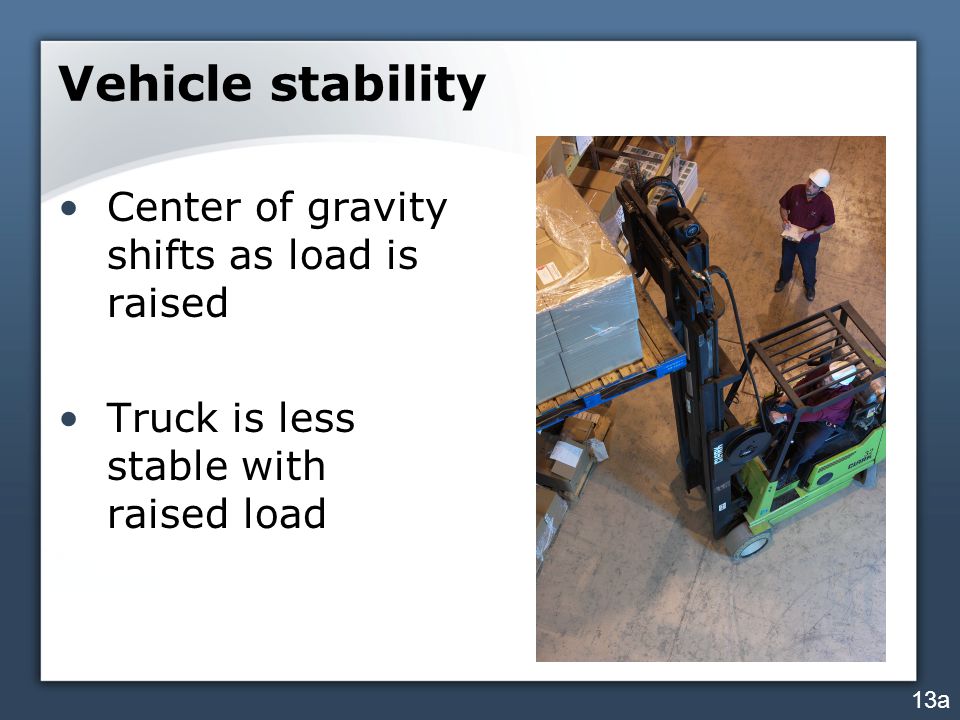

As a general rule the load center is 24-inches from the face of the forks or the center point of a 48-inch by 48-inch pallet. Remember a forklift is less stable with a load raised high especially while moving. The traditional model of the forklift stability triangle is useful but it leaves out one important thing.

The CAMD forks without extensions have a total length of 48 inches with a load center of 24 inches. When the load is lifted the center of gravity moves forward. Care must be taken to maintain the center of gravity within the stability triangle of the forklift by not lifting more than the maximum allowable given the load center.

Check that the overhead clearance is adequate before raising loads. A safe load at 4 inches off the ground may tip the forklift at 4 feet up. In warehouses with high storage racks the lightest loads should be placed on the top racks and the heavier loads on the bottom racks.

The lift truck also has a center of gravity which shifts once the truck picks up a load. After the forklift has driven the load to the designated area the operator needs to set down the load carefully. Be aware that fork extenders make the load less stable.

Telehandler Forklift Telehandler Tyres. Operating a forklift requires additional skills and experience because its design makes it less stable and much heavier than cars. For a stationary forklift provided this centre of mass is within the stability triangle the forklift will neither tip forwards or sideways.

It is often safer to move a wide heavy load with a crane rather than a forklift. The operator must stay on the forklift when the load is in a raised position. The longer the forks the less stable the load.

Tyres play a vital part in the stability of telehandlers. Always keep in mind that the load is less stable when doing turn and when the load is in a raised position. The rear-wheel steering also causes the rear end of the forklift to swing out when it turns.

The maximum weight a forklift can safely carry at a specified load center. When a load is raised the lift truck is less stable. Never turn a forklift on a grade.

The center of gravity shifts when the load is raised. Driving a forklift is different from driving a car. None of the above.

If you have a stable pallet the best thing to do is tilt as far back as the machine will let you. Should only be used by a trained certificated and competent operator. A laden forklift cannot use its maximum braking capacity because the load will slide or fall from the tines or the forklift will tip forwards.

If an operator jumps from a tipping forklift the chances of serious injury are high. Lift loads greater than the capacity of the forklift Move a load that appears unsuitable or unstable including on a damaged pallet Lift load with attachments unless trained certified and authorised to do so Travel with a bulky load that blocks your view Travel with a raised load unless the forklift is designed specifically for this Leave. The horizontal distance from the vertical face of the forks to the center of the gravity load.

Setting Down A Load. As a load moves upward it shifts the trucks center of gravity forward. Dont back up until the forks are free.

Tipping over is the biggest danger for a forklift operator. The Forklifts Center. The front tires come off of the ground.

Drive loaded trucks forward going up a ramp with the load upgrade and drive in reverse going down a ramp with the load upgrade. For more information see the Workplace. Forklift Training – General Operators must be trained and evaluated Only drive the types of trucks on which you have been trained Overview 1a Forklift rules Dont stand or pass under raised forks Only handle stable loads within trucks rated capacity 2a Forklift rules Use a safety platform to lift people Only use approved trucks in hazardous locations Look in direction of travel 2b Dont.

When the forklift is stationary the only force acting on this point is the force of gravity vertically down.

Fork Lift Training On 21th Sep 13

Fork Lift Training On 21th Sep 13

5 Things You Probably Should Know About Forklift Safety Aaa Forklifts

5 Things You Probably Should Know About Forklift Safety Aaa Forklifts

Safe Operation Of Forklifts Ppt Download

Safe Operation Of Forklifts Ppt Download

Powered Industrial Trucks Class Iv Operator Training Ppt Video Online Download

Powered Industrial Trucks Class Iv Operator Training Ppt Video Online Download

4 Causes Of Forklift Tip Overs How To Massively Reduce The Risk

4 Causes Of Forklift Tip Overs How To Massively Reduce The Risk

Https Osha Washington Edu Sites Default Files Documents Osha7005 Danastahl Pdf

Http Www Assesstolift Com Au Studyguide Pdf

Forklift Training Operators Must Be Trained And Evaluated In A Regular Bases Only Drive The Types Of Forklifts On Which You Have Been Trained 1a Ppt Download

Forklift Training Operators Must Be Trained And Evaluated In A Regular Bases Only Drive The Types Of Forklifts On Which You Have Been Trained 1a Ppt Download

The 10 Greatest Risks When Operating A Forklift Truck Part 5 Reversing Simplexity

The 10 Greatest Risks When Operating A Forklift Truck Part 5 Reversing Simplexity

Forklift Training General Ppt Download

Forklift Training General Ppt Download

Https Www Ispettorato Gov It It It Attivita Documents Attivita Internazionale Load Lifting Equipment Used To Lift Workers National Practices When Using A Forklift Truck Pdf

Forklift Safety R J Material Handling

Forklift Safety R J Material Handling

The 10 Greatest Risks When Operating A Forklift Truck Part 3 Having The Forks Raised Too High When Moving Loads Simplexity

The 10 Greatest Risks When Operating A Forklift Truck Part 3 Having The Forks Raised Too High When Moving Loads Simplexity