The Impact on Warehouse Aisle Width by Forklift Type Counterbalance Lift Truck 11-13 ft. OSHAs general requirement for aisles and passagewaysis that sufficient safe clearances must be provided where mechanical equipment is used.

Floor Marking Color Code Guide Osha Standards Brady

Floor Marking Color Code Guide Osha Standards Brady

Therefore any width 2 inches or more is considered acceptable.

Forklift aisle width osha. In offices minimum height and width requirements apply to emergency exit aisles. You should examine your forklift model and configuration as different types of forklifts can impact how you determine the optimal distance between pallet racking and industrial shelving. If you still have questions about forklift traffic safety or OSHA-compliant forklift training call us at 888 278-8896.

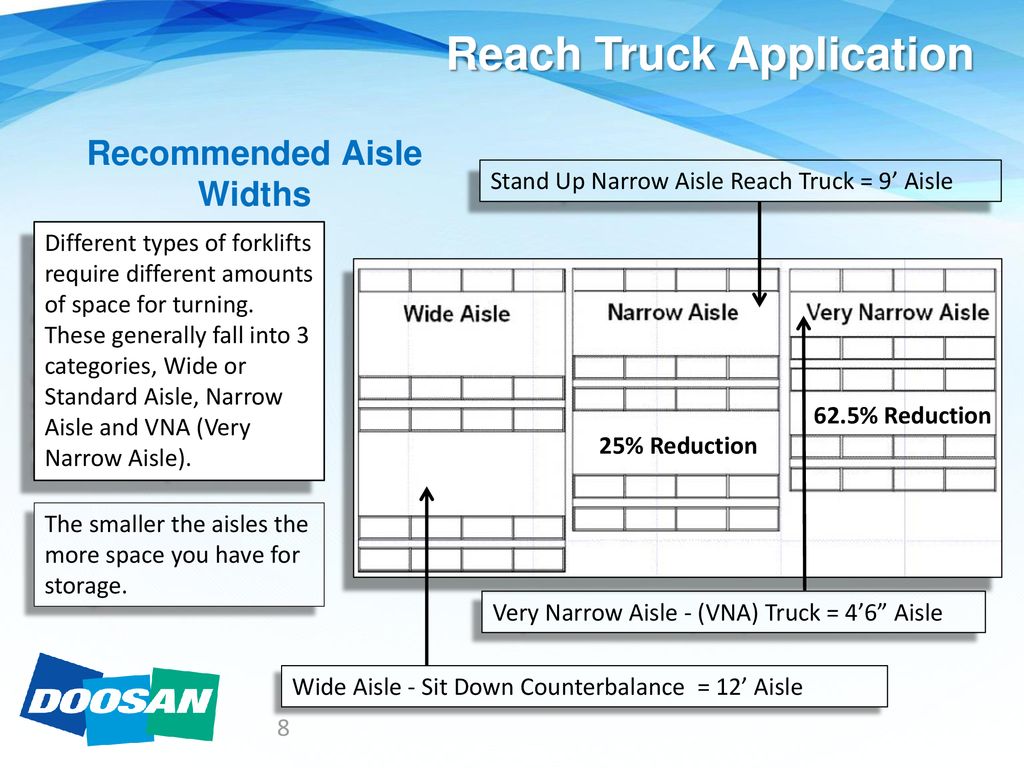

But it is not without a disadvantage it requires an electric forklift such as a reach truck or order picker to be driven in much tighter aisle width. The width required will vary depending upon how the aisle is utilized in the workplace – as aisles that utilize forklift and truck traffic will need to be wider than aisles for pedestrian traffic. FLC has the needed forklift and pedestrian safety training you need that meet or exceed OSHAs forklift and pedestrian safety requirements.

Aisle Single Deep Three to Four High Pallet Stacking. When you are picking up very wide loads be sure to set your aisle to at least 2 feet wider than the width of the load or the aisle dimensions above whichever is wider. The width will vary depending upon how the aisle is utilized in the workplace as aisles used for forklift trucks or other mechanical equipment.

Forklift aisle widths correspond to the technical specifications provided by forklift manufacturers which include data on each type and model of machine they sell. Forklift aisle widths correspond to the technical specifications provided by forklift manufacturers which include data on each type and model of machine they sell. Rack to Rack dimensions require 72 inch aisles due to 3 inch pallet overhang.

Narrow aisle storage systems provide more storage space but require reach trucks and order pickers to operate in much narrower aisle widths. These include requirements that aisles be inside OSHAs general requirement for aisles and passageways is that sufficient safe clearances must be provided where mechanical equipment is used. The minimum requirement is 28 inches wide and 7 feet 6 inches high.

The great benefit of having a narrow aisle storage system is that it grants more storage rooms for goods and materials to be stacked. Floor Tape 17 Forklift Safety 49 Gemba 16 GHS. Load Length 12 in.

Clearance signs to warn of clearance limits shall be provided An OSHA letter of interpretation of the aisle marking rule at 29 CFR 191022b says The recommended width of aisles is at least 3 feet wider than the largest equipment to be utilized or a minimum of 4 feet. Permanent aisles and passageways shall be appropriately marked. These specs can be used to obtain the data needed to design an installation for example with drive-in racksThe key data are the width of the aisle required to operate the machine the lifting height for the load and the height.

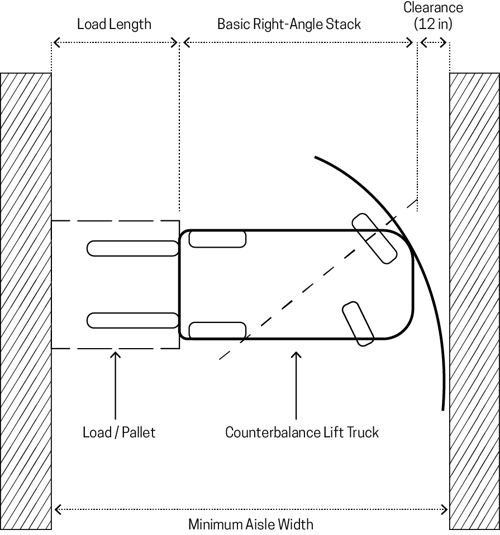

Remember that this is just a start to your assessment practice. According to the forklift specs the model you are considering has a Basic Right Angle Stack spec of 86 inches. Hazards of Operating Electric Forklifts in Narrow Aisles.

A very narrow aisle turret truck uses an aisle of 10 inches to 18 inches wider than the width of the lift truck assuming a 48 inch length x 40 inch width load. Conventional rack storage systems were designed for the counterbalanced lift truck which requires about a 12 ft 144 in aisle width. The standard counterbalance sit down or stand up lift truck is widely used today and uses a 90 degree right angle turn and the operator drives up to the product or racking.

As a general rule youll need aisles of sufficient width to allow the safe evacuation of all the people who work on the floor served by the aisle. Basic Right Angle Stacking Width 48 in. These specs can be used to obtain the data needed to design an installation for example with drive-in racksThe key data are the width of the aisle required to operate the machine the lifting height for the load and the height.

Order Picker Order Selector Stock Picker. Clearance 146 in. Wendell Assistant Regional Administrator for Compliance Corrected April 17 2009.

In a warehouse minimizing the working aisle width and maximizing throughput allows the best possible utilization of bulk storage and picking profiles with in the same environment using the same truck. The recommended width of aisles is at least 3 feet wider than the largest equipment to be utilized or a minimum of 4 feet. Clear aisles can be as narrow as 66 inches 55 feet.

If you are laying out a facility what criteria should you use for rack aisle width. Narrow aisle stand-up counterbalanced forklifts will require aisle widths of approximately 11 feet for handling any standard 48 long pallet loads for right angle stacking of loads in storage racking. As part of your efforts to minimize warehouse aisle width you need to consider the forklift you use as well.

Exceptions to Forklift Aisle Width Dimensions Read This Sometimes wide-aisle forklifts will lift up a load that is not your standard 48 x 40 pallet. Industrial width there are specific aisle requirements which are set for industrial aisles. This is true for most narrow aisle forklifts that are rated capacities of 3000 lbs.

The recommended width of aisle markings varies from 2 inches to 6 inches. But for reach truck selective rack applications these aisle sizes are often eye balled or given a 12 width no matter what type of forklift is using the aisles. General aisle configuration guidelines.

This is in terms of width and they should be 4 feet at least and 3-feet wider than largest available equipment passing through them.

Warehouse Aisle Dimensions For Forklifts Fallsway

Warehouse Aisle Dimensions For Forklifts Fallsway

Powered Industrial Trucks Etool Understanding The Workplace Narrow Aisles

Powered Industrial Trucks Etool Understanding The Workplace Narrow Aisles

What Are Osha Aisle Marking Requirements Creative Safety Supply

What Are Osha Aisle Marking Requirements Creative Safety Supply

Determining Warehouse Aisle Width Forkliftcertification Com

Determining Warehouse Aisle Width Forkliftcertification Com

Https Osha Oregon Gov Edu Documents Workshop Materials 1 251w Pdf

Toyota Industrial Equipment Guide To Proven Warehouse Solutions

Toyota Industrial Equipment Guide To Proven Warehouse Solutions

Floor Marking Guidelines A Step By Step Guide Kasama Us

Floor Marking Guidelines A Step By Step Guide Kasama Us

Warehouse Striping Osha Guidance For Floor Marking Consistency

Warehouse Striping Osha Guidance For Floor Marking Consistency

Use Guard Rails To Help Manager Forklift Traffic In Warehouses

Use Guard Rails To Help Manager Forklift Traffic In Warehouses

A Guide To Forklift Aisle Widths Cisco Eagle

A Guide To Forklift Aisle Widths Cisco Eagle

What Is Aisle Spacing An Aisle Space Can Be Understood As The By Stitchdiary Medium

What Is Aisle Spacing An Aisle Space Can Be Understood As The By Stitchdiary Medium

Why Aisle Width Matters When It Comes To Pallet Rack Safety

Why Aisle Width Matters When It Comes To Pallet Rack Safety

The Very Narrow Aisle Flexi Forklift Toyota Lift Equipment

The Very Narrow Aisle Flexi Forklift Toyota Lift Equipment

Pin By Priyatna Pribadi On Rcheuli Warehouse Layout Warehouse Design Warehouse

Pin By Priyatna Pribadi On Rcheuli Warehouse Layout Warehouse Design Warehouse

Reducing Your Aisle Width For High Density Warehouse Storage Next Level Storage Solutions Warehouse Layout Warehouse Shelving Office Bathroom Design

Reducing Your Aisle Width For High Density Warehouse Storage Next Level Storage Solutions Warehouse Layout Warehouse Shelving Office Bathroom Design

Osha Top 10 2017 Violations And How They Affect Warehousing

Osha Top 10 2017 Violations And How They Affect Warehousing

Https Precisionfloormarking Com Wp Content Uploads 2017 05 Osha Aisle Marking Tips Pdf