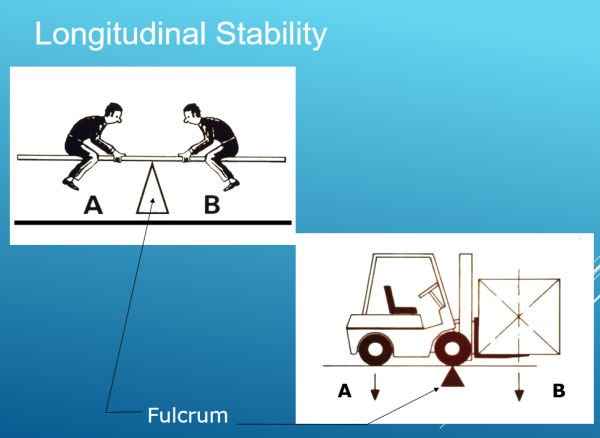

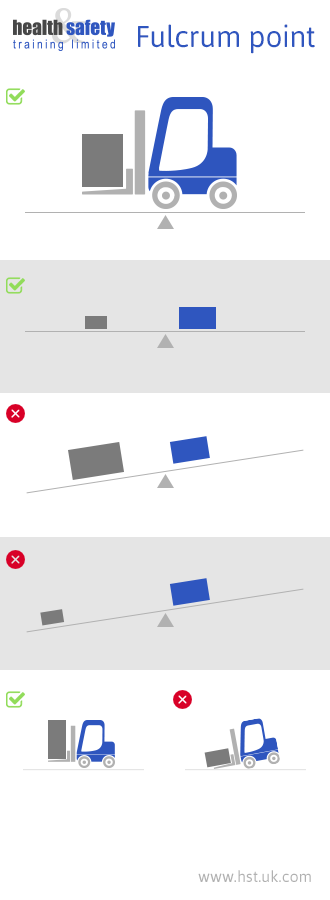

FULCRUMA fulcrum is the support point for a lever used to raise or lower something. The point at which a lever turns Question 2.

Logistique Magasinage Manutention Conduitechariot Reglesusa Fonctionnement Contrepoids Howworkliftworks An Formation Personnelle Autoformation

Logistique Magasinage Manutention Conduitechariot Reglesusa Fonctionnement Contrepoids Howworkliftworks An Formation Personnelle Autoformation

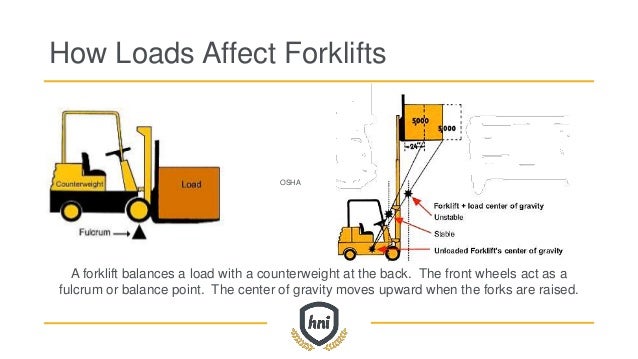

The operator must keep the fulcrum point in mind when lifting loads overhead when the forklift is not totally level.

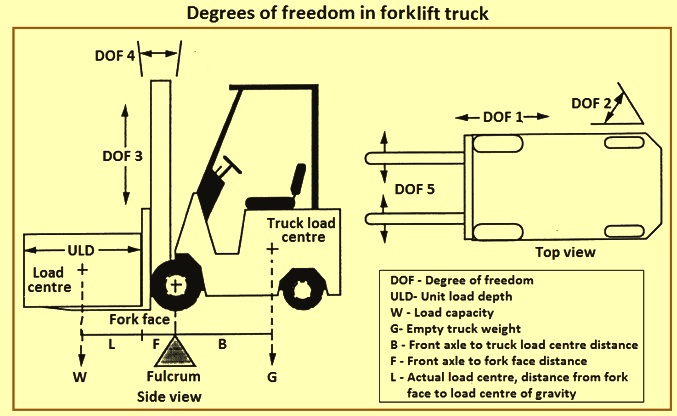

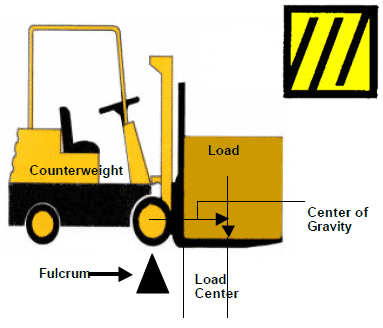

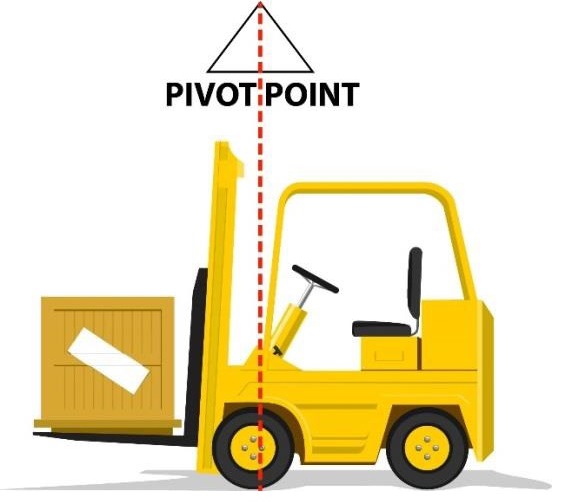

Fulcrum point on a forklift. Load Moment Weight X Distance. The fulcrum point of a forklift is also known as the pivot point as it is where a forklift can pivot or tip forward if a load it too heavy. In order for this principle to work for a lift truck the load of the forks must be.

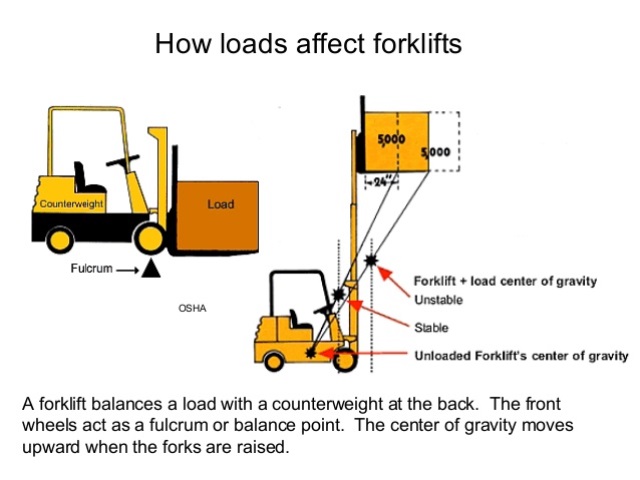

Front Wheels Question 1. Load Moment is the product of the objects weight multiplied by the objects distance from the fulcrum which is a fixed point that acts as the pivot point. When carrying a load your forks should always point toward the top of the ramp so the load will not fall off.

The point at which a bar or something that is balancing is supported or balances. What do you to explain the complex concept of the danger of tipping over a forklift without risking a life. Make sure the forklift is level before lifting a load overhead.

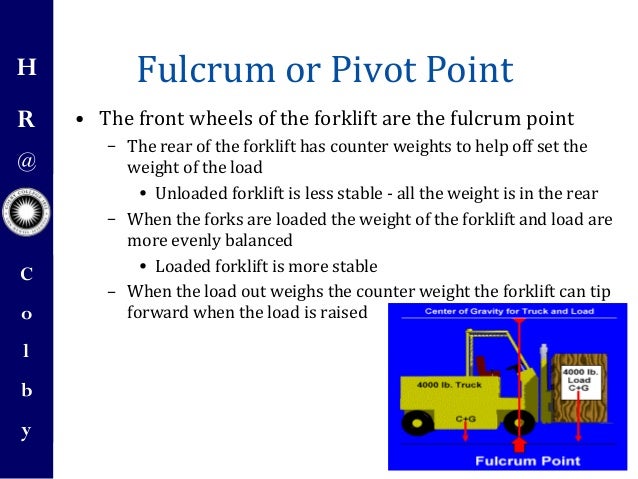

The fulcrum or pivot point is the dividing line between the machines weight and the loads weight. Obviously this is a bit of an issue as outside of the test weights used by engineers and manufacturers 48 cubes with an even weight distribution a load are rarely encountered by your average forklift operator. The forward wheels are the fulcrum.

The fulcrum is where a vertical line drawn through the centre of the front axle would meet the ground. A fulcrum is the point or support on which a lever turns. An easy way to remember this is the fulcrum is where the front wheels touch the ground.

Tips the balance in its favor Ives Definition. Weight Counterweight Everything behind the fulcrum acts as a counterweight. What happens at the heavy end of a fulcrum.

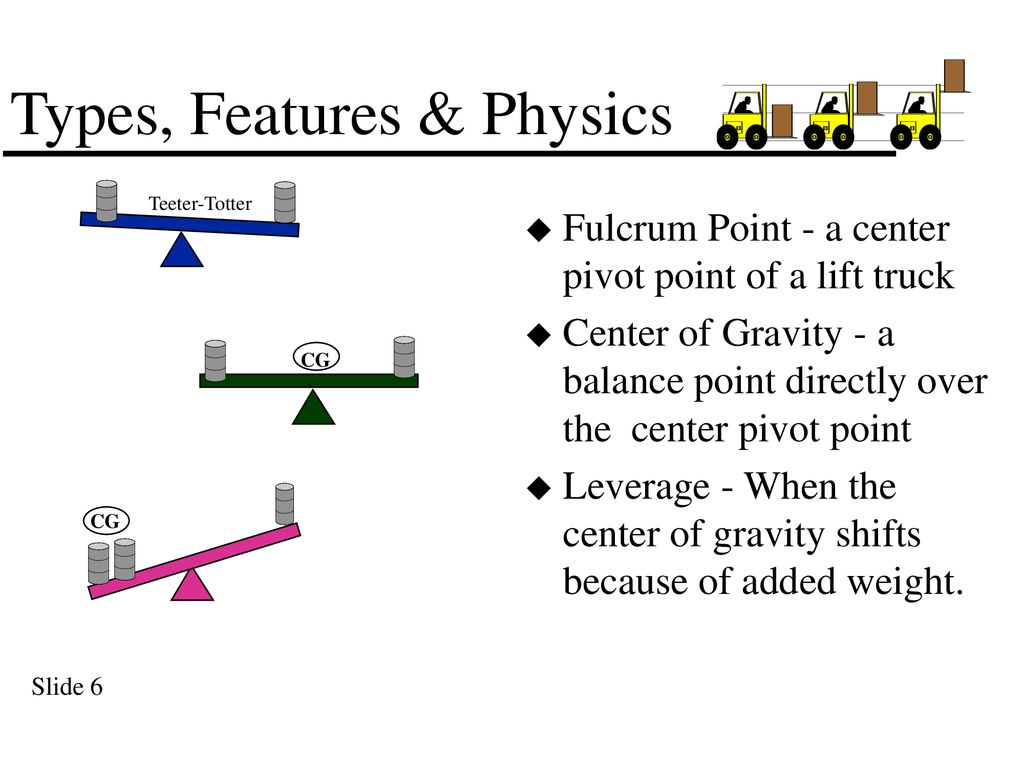

The point of balance on a forklift is called the fulcrum. The fulcrum is the central pivot point of a seesaw. The front axle is the fulcrum of the forklift where the counterweight and the load find balance.

FORKLIFT OPERATOR SAFETY TRAINING Conclusion Forklifts are more hazardous than most people usually perceive them to be Pre-use inspections must be performed before each day or shift It is important to understand how the load will affect the stability of the forklift The operator must always be on the look out for hazards and pedestrians What Should You. Basically THE POINT AROUND WHICH A LEVER MOVES IS CALLED FULCRUMAn easy way to understand what a fulcrum means. Forklift America reports most forklifts indicate their load capacity on their respective data plates.

On a seesaw the fulcrum is the center. What happens at the. Forklift Safety 6 This material is for training use only The lift truck is based on the principle of two weights balanced on opposite sides of a pivot point _____ _____.

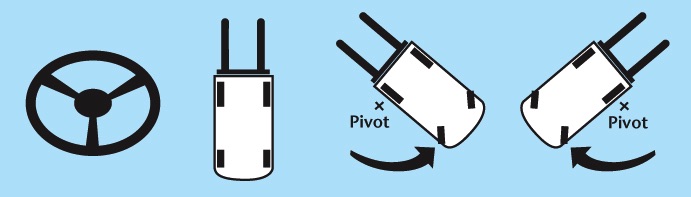

On a sit-down counterbalanced forklift the fulcrum or pivot point is the axle of the front wheels. Herein what is the fulcrum point on a forklift. Remember the 3 point triangle rule of keeping the load within the fulcrum when lifting.

On a sit-down counterbalanced forklift the fulcrum or pivot point is the axle of the front wheels. Where is the fulcrom point on Counterbalance Forklift. This is the same principle used for a teeter-totter.

It is this product or Load Moment which determines how much overturning force is being applied to the forklift. Maintaining Stability On a forklift the fulcrum is the front wheels. While traveling empty on a ramp your forks should always point downhill.

Fulcrum the less stable the load. 3D Animation of course. Fulcrum Point Question 1.

This is an except from MANCOMMs forklift training video. The closer the load is moved to the fulcrum the more the forklift is able to lift. Any time the loads center of gravity is moved away from the fulcrum point the units maximum lift capacity decreases a process known as down-rating.

If a forklift starts to tip over while youre operating it do not try to jump clear of the machine. Stability is created through a cantilever system similar to a teeter-totter two sides balanced on a pivot point the fulcrum. On a forklift the forward wheels are the fulcrum.

You can think of it like a see-saw in a childrens park where if both sides have equal weight then it is balanced but if the load side is heavier the load must be moved closer to the fulcrum point to maintain the balance. The load on the. The only major difference between a forklift and a seesaw is that the forklift counterweight should always provide more force than the load so the forklift does not tip forward.

The animation demonstrates how forklifts operate much better than video ever could.

Traknus Utama How Forklifts Safely Carry And Lift Heavy Loads

Traknus Utama How Forklifts Safely Carry And Lift Heavy Loads

Forklift Training Ppt Download

Forklift Training Ppt Download

Powered Industrial Trucks Class Iv Operator Training Ppt Video Online Download

Powered Industrial Trucks Class Iv Operator Training Ppt Video Online Download

Http Www Assesstolift Com Au Studyguide Pdf

April 2014 Training And Educating Forklift Operators By Craig Hamelund Oregon Osha Training Specialist Many Forklift Operators Have Learned Their Jobs Exclusively Through Practical Experience Is Practical Experience Safe Enough Forklift Operators Must

April 2014 Training And Educating Forklift Operators By Craig Hamelund Oregon Osha Training Specialist Many Forklift Operators Have Learned Their Jobs Exclusively Through Practical Experience Is Practical Experience Safe Enough Forklift Operators Must

Forklift Truck See Saw Analogy In Balance

Forklift Truck See Saw Analogy In Balance

Forklift Course Training Notes Manualzz

Forklift Course Training Notes Manualzz

Oshacademy Course 725 Powered Industrial Truck Safety

Oshacademy Course 725 Powered Industrial Truck Safety

Forklift Attachments And Forklift Stability Reconditionedforklifts Com

An Accident Involving A Forklift Truck Ppt Download

An Accident Involving A Forklift Truck Ppt Download

Power Industrial Truck Training Ppt Download

Power Industrial Truck Training Ppt Download

Forklift Stability Triangle Forklift Data Plate Explained Lateral Instability

Forklift Stability Triangle Forklift Data Plate Explained Lateral Instability

Forklift Capacity Calculator Lift Truck Load Center Calculator

Forklift Capacity Calculator Lift Truck Load Center Calculator

Train The Trainer Forklift Safety

Train The Trainer Forklift Safety

Health Safety Jargon Buster Terms Health Safety Training Ltd

Health Safety Jargon Buster Terms Health Safety Training Ltd