View Forklift Battery Charging Area Requirements Images. Forklift battery charging safety starts here with expert advice from new pig! Like many work tasks, charging forklift batteries can create more than one hazard. Forklift batteries produce hydrogen and oxygen gases as they charge. Both have their own kinds of systems, setups, charging requirements, and price tags. Establishing an area for battery charging is also. Charging forklift batteries requires training and caution due to the batteries' weight, the corrosive sulfuric acid contained within, the the occupational safety and health administration (osha) standard, 29 cfr 1910.178(g), lays out the safety requirements for forklift battery charging areas. They also need to be taught forklift battery charging station safety requirements to help avoid injuries. Forklift battery charging methods the discovery process. This video helps you determine which option. Why do forklift battery rooms need special ventilation systems? While it looks like lead acids will be the industry leader through 2020 due to price and. To mitigate this, air quality should be frequently monitored to ensure hydrogen levels stay below 2% at all times. The simple route is to use a trusted online calculator, like the bhs hydrogen gas ventilation calculator for forklift battery charging areas. The electric forklift battery differs from standard lead acid batteries and has different servicing requirements. Ventilating your charging area is essential in ensuring operator safety, since charging forklift batteries produces hydrogen gas, which is difficult to detect and extremely dangerous.

How A Forklift Battery Weight Impacts Your Operation

Forklift Battery Chargers Total Warehouse. Establishing an area for battery charging is also. Forklift battery charging safety starts here with expert advice from new pig! Ventilating your charging area is essential in ensuring operator safety, since charging forklift batteries produces hydrogen gas, which is difficult to detect and extremely dangerous. Both have their own kinds of systems, setups, charging requirements, and price tags. Charging forklift batteries requires training and caution due to the batteries' weight, the corrosive sulfuric acid contained within, the the occupational safety and health administration (osha) standard, 29 cfr 1910.178(g), lays out the safety requirements for forklift battery charging areas. The simple route is to use a trusted online calculator, like the bhs hydrogen gas ventilation calculator for forklift battery charging areas. Forklift batteries produce hydrogen and oxygen gases as they charge. The electric forklift battery differs from standard lead acid batteries and has different servicing requirements. Like many work tasks, charging forklift batteries can create more than one hazard. To mitigate this, air quality should be frequently monitored to ensure hydrogen levels stay below 2% at all times. While it looks like lead acids will be the industry leader through 2020 due to price and. This video helps you determine which option. They also need to be taught forklift battery charging station safety requirements to help avoid injuries. Forklift battery charging methods the discovery process. Why do forklift battery rooms need special ventilation systems?

(1) battery charging areas are specifically regulated by another cal/osha standard. Our goal is to increase the productivity of. This video helps you determine which option. · industrial batteries are typically designed to last at least 1 if an acid spillage occurs, contact the gb battery supplier in your area. Charging forklift batteries requires training and caution due to the batteries' weight, the corrosive sulfuric acid contained within, the the occupational safety and health administration (osha) standard, 29 cfr 1910.178(g), lays out the safety requirements for forklift battery charging areas. It will always be a requirement especially if the. The gas is colorless, very poisonous, flammable and has the odor of rotten eggs.

The hazards and recommended practices for charging and changing batteries are requirements and recommended practices include:

Over charging and opportunity charging. Ventilating your charging area is essential in ensuring operator safety, since charging forklift batteries produces hydrogen gas, which is difficult to detect and extremely dangerous. Our goal is to increase the productivity of. A forklift battery charging station should be used only for changing and charging batteries, and meet the following conditions: Electric or battery powered forklift trucks are used in many industries for a variety of applications. Forklift battery charging safety starts here with expert advice from new pig! This guide covers how charging a forklift battery affects its performance and life. · industrial batteries are typically designed to last at least 1 if an acid spillage occurs, contact the gb battery supplier in your area. Forklift battery charging area requirements must be strictly enforced to prevent accidents. · charging batteries that are as little as 1 low on water can cause damage to the entire battery that can never be repaired. Why do forklift battery rooms need special ventilation systems? Charging forklift batteries requires training and caution due to the batteries' weight, the corrosive sulfuric acid contained within, the the occupational safety and health administration (osha) standard, 29 cfr 1910.178(g), lays out the safety requirements for forklift battery charging areas. A lot of traditional lead acid batteries of 250 amp hours and under (deep cycle. Over charging and opportunity charging. An overfilled battery can spill over the this bubbling process helps mix the acid inside the battery for uniform acidity over all areas of the. Forklift batteries can be heavy and dangerous if not handled properly, so it's important to be educated on the correct way to handle them. Battery chargingselect the proper location charging operations should be conducted in an area with good natural eye protection and an eyewash/emergency shower are essential requirements. Flooded or wet cell batteries should be equalized on a regular basis. • the age of your forklift, is the forklift operating correctly? Why does the battery smell so acidic? They also need to be taught forklift battery charging station safety requirements to help avoid injuries. Though lithium batteries are much lighter than lead acid batteries, ballast is added to ensure the. Both have their own kinds of systems, setups, charging requirements, and price tags. Call our team on 01709 549643 with your enquiries. Battery charging station layout and area requirements. Forklift batteries produce hydrogen and oxygen gases as they charge. The gas is colorless, very poisonous, flammable and has the odor of rotten eggs. This guide focuses on flooded lead acid, but many of the points are the life of a forklift battery is measured in charge cycles (a charge cycle being 1 discharge followed by full recharge), and manufacturers today are. Remember that lead acid batteries should be charged at 80. Never inspect a charging battery with an open. Allow the battery to charger a full 8 hours through the gassing stage.

Electric Forklift Charging Forklift Batteries Safely

Matthai Material Handling Forklift Batteries And Chargers. To mitigate this, air quality should be frequently monitored to ensure hydrogen levels stay below 2% at all times. Like many work tasks, charging forklift batteries can create more than one hazard. Both have their own kinds of systems, setups, charging requirements, and price tags. While it looks like lead acids will be the industry leader through 2020 due to price and. The electric forklift battery differs from standard lead acid batteries and has different servicing requirements. They also need to be taught forklift battery charging station safety requirements to help avoid injuries. Forklift battery charging methods the discovery process. The simple route is to use a trusted online calculator, like the bhs hydrogen gas ventilation calculator for forklift battery charging areas. Why do forklift battery rooms need special ventilation systems? Forklift batteries produce hydrogen and oxygen gases as they charge. Charging forklift batteries requires training and caution due to the batteries' weight, the corrosive sulfuric acid contained within, the the occupational safety and health administration (osha) standard, 29 cfr 1910.178(g), lays out the safety requirements for forklift battery charging areas. Establishing an area for battery charging is also. Ventilating your charging area is essential in ensuring operator safety, since charging forklift batteries produces hydrogen gas, which is difficult to detect and extremely dangerous. Forklift battery charging safety starts here with expert advice from new pig! This video helps you determine which option.

Home Forklift Batteries Fantastic Prices Batterytechnologies

Forklift Battery Charging Area Banners And Signs Sku 5926 The 5s Superstore. Ventilating your charging area is essential in ensuring operator safety, since charging forklift batteries produces hydrogen gas, which is difficult to detect and extremely dangerous. Forklift battery charging methods the discovery process. The simple route is to use a trusted online calculator, like the bhs hydrogen gas ventilation calculator for forklift battery charging areas. Establishing an area for battery charging is also. This video helps you determine which option. To mitigate this, air quality should be frequently monitored to ensure hydrogen levels stay below 2% at all times. Forklift battery charging safety starts here with expert advice from new pig! They also need to be taught forklift battery charging station safety requirements to help avoid injuries. Like many work tasks, charging forklift batteries can create more than one hazard. Charging forklift batteries requires training and caution due to the batteries' weight, the corrosive sulfuric acid contained within, the the occupational safety and health administration (osha) standard, 29 cfr 1910.178(g), lays out the safety requirements for forklift battery charging areas. Why do forklift battery rooms need special ventilation systems? Both have their own kinds of systems, setups, charging requirements, and price tags. The electric forklift battery differs from standard lead acid batteries and has different servicing requirements. Forklift batteries produce hydrogen and oxygen gases as they charge. While it looks like lead acids will be the industry leader through 2020 due to price and.

Powered Industrial Trucks Etool Types Fundamentals Power Sources Electric

Equalization Charging Keeps Your Lift Truck Running Longer Tmhoh. This video helps you determine which option. Establishing an area for battery charging is also. They also need to be taught forklift battery charging station safety requirements to help avoid injuries. Forklift batteries produce hydrogen and oxygen gases as they charge. Charging forklift batteries requires training and caution due to the batteries' weight, the corrosive sulfuric acid contained within, the the occupational safety and health administration (osha) standard, 29 cfr 1910.178(g), lays out the safety requirements for forklift battery charging areas. Why do forklift battery rooms need special ventilation systems? While it looks like lead acids will be the industry leader through 2020 due to price and. The simple route is to use a trusted online calculator, like the bhs hydrogen gas ventilation calculator for forklift battery charging areas. The electric forklift battery differs from standard lead acid batteries and has different servicing requirements. Forklift battery charging methods the discovery process. Like many work tasks, charging forklift batteries can create more than one hazard. To mitigate this, air quality should be frequently monitored to ensure hydrogen levels stay below 2% at all times. Ventilating your charging area is essential in ensuring operator safety, since charging forklift batteries produces hydrogen gas, which is difficult to detect and extremely dangerous. Both have their own kinds of systems, setups, charging requirements, and price tags. Forklift battery charging safety starts here with expert advice from new pig!

Changing And Charging A Forklift Battery Safely

Forklift Battery Charging Area No Smoking Or Open Flame Sign Sku S2 4126. While it looks like lead acids will be the industry leader through 2020 due to price and. Forklift batteries produce hydrogen and oxygen gases as they charge. Why do forklift battery rooms need special ventilation systems? Charging forklift batteries requires training and caution due to the batteries' weight, the corrosive sulfuric acid contained within, the the occupational safety and health administration (osha) standard, 29 cfr 1910.178(g), lays out the safety requirements for forklift battery charging areas. Forklift battery charging methods the discovery process. Ventilating your charging area is essential in ensuring operator safety, since charging forklift batteries produces hydrogen gas, which is difficult to detect and extremely dangerous. They also need to be taught forklift battery charging station safety requirements to help avoid injuries. Both have their own kinds of systems, setups, charging requirements, and price tags. The electric forklift battery differs from standard lead acid batteries and has different servicing requirements. Forklift battery charging safety starts here with expert advice from new pig! Like many work tasks, charging forklift batteries can create more than one hazard. The simple route is to use a trusted online calculator, like the bhs hydrogen gas ventilation calculator for forklift battery charging areas. To mitigate this, air quality should be frequently monitored to ensure hydrogen levels stay below 2% at all times. Establishing an area for battery charging is also. This video helps you determine which option.

Recharge Your Forklift Fleet Ftw The Forktruck Warehouse

Creating An Optimal Forklift Battery Charging Station. Both have their own kinds of systems, setups, charging requirements, and price tags. This video helps you determine which option. The simple route is to use a trusted online calculator, like the bhs hydrogen gas ventilation calculator for forklift battery charging areas. Like many work tasks, charging forklift batteries can create more than one hazard. Ventilating your charging area is essential in ensuring operator safety, since charging forklift batteries produces hydrogen gas, which is difficult to detect and extremely dangerous. The electric forklift battery differs from standard lead acid batteries and has different servicing requirements. Establishing an area for battery charging is also. Forklift battery charging methods the discovery process. To mitigate this, air quality should be frequently monitored to ensure hydrogen levels stay below 2% at all times. They also need to be taught forklift battery charging station safety requirements to help avoid injuries. While it looks like lead acids will be the industry leader through 2020 due to price and. Why do forklift battery rooms need special ventilation systems? Forklift battery charging safety starts here with expert advice from new pig! Forklift batteries produce hydrogen and oxygen gases as they charge. Charging forklift batteries requires training and caution due to the batteries' weight, the corrosive sulfuric acid contained within, the the occupational safety and health administration (osha) standard, 29 cfr 1910.178(g), lays out the safety requirements for forklift battery charging areas.

Designing A Safe Forklift Battery Charging Room Adaptalift Group

Forklift Battery Topping Hoppecke Industrial Batteries. Charging forklift batteries requires training and caution due to the batteries' weight, the corrosive sulfuric acid contained within, the the occupational safety and health administration (osha) standard, 29 cfr 1910.178(g), lays out the safety requirements for forklift battery charging areas. Forklift battery charging safety starts here with expert advice from new pig! Forklift batteries produce hydrogen and oxygen gases as they charge. They also need to be taught forklift battery charging station safety requirements to help avoid injuries. The simple route is to use a trusted online calculator, like the bhs hydrogen gas ventilation calculator for forklift battery charging areas. Establishing an area for battery charging is also. This video helps you determine which option. Like many work tasks, charging forklift batteries can create more than one hazard. While it looks like lead acids will be the industry leader through 2020 due to price and. Ventilating your charging area is essential in ensuring operator safety, since charging forklift batteries produces hydrogen gas, which is difficult to detect and extremely dangerous. Why do forklift battery rooms need special ventilation systems? Forklift battery charging methods the discovery process. To mitigate this, air quality should be frequently monitored to ensure hydrogen levels stay below 2% at all times. Both have their own kinds of systems, setups, charging requirements, and price tags. The electric forklift battery differs from standard lead acid batteries and has different servicing requirements.

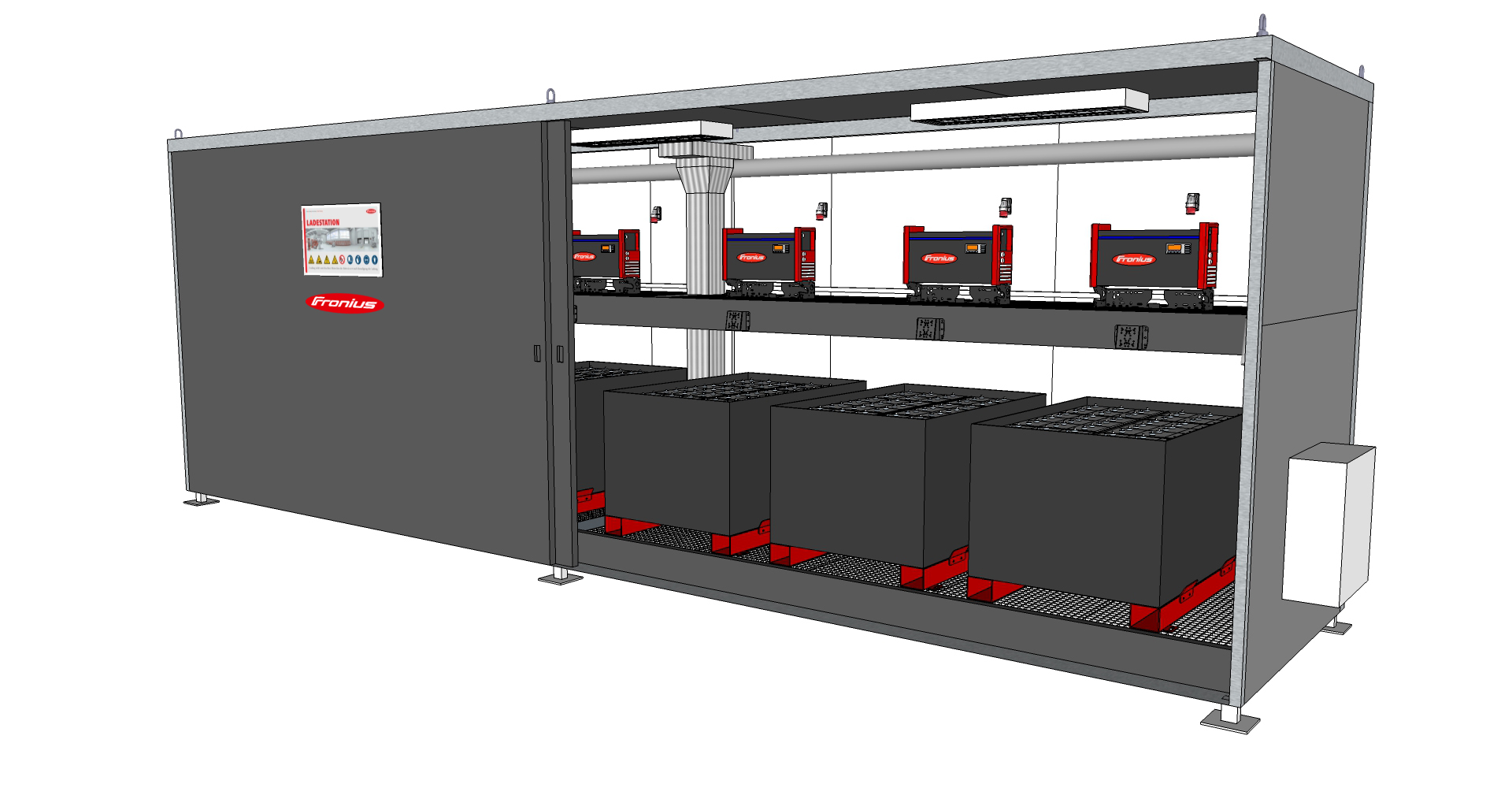

Fronius Energy Hub Allows Flexible Outdoor Battery Charging Logistics Business Magazine

Designing A Safe Forklift Battery Charging Room Adaptalift Group. To mitigate this, air quality should be frequently monitored to ensure hydrogen levels stay below 2% at all times. Establishing an area for battery charging is also. The simple route is to use a trusted online calculator, like the bhs hydrogen gas ventilation calculator for forklift battery charging areas. Forklift battery charging methods the discovery process. This video helps you determine which option. Charging forklift batteries requires training and caution due to the batteries' weight, the corrosive sulfuric acid contained within, the the occupational safety and health administration (osha) standard, 29 cfr 1910.178(g), lays out the safety requirements for forklift battery charging areas. Like many work tasks, charging forklift batteries can create more than one hazard. The electric forklift battery differs from standard lead acid batteries and has different servicing requirements. Forklift battery charging safety starts here with expert advice from new pig! Both have their own kinds of systems, setups, charging requirements, and price tags. They also need to be taught forklift battery charging station safety requirements to help avoid injuries. Ventilating your charging area is essential in ensuring operator safety, since charging forklift batteries produces hydrogen gas, which is difficult to detect and extremely dangerous. While it looks like lead acids will be the industry leader through 2020 due to price and. Forklift batteries produce hydrogen and oxygen gases as they charge. Why do forklift battery rooms need special ventilation systems?