View Forklift Pre Shift Inspection Gif. In 29 cfr 1910.178(g)(7), osha requires all forklifts be examined at least once a day before they are placed into service. If the forklift operator finds any malfunctions or defects during the inspection, the operator must notify his or her supervisor, noting that the vehicle is not safe to use. Malfunction of the forklift brakes can result in serious damage, injury or death, making regular inspection a must. Для просмотра онлайн кликните на видео ⤵. One item of focus is the brakes. We have found that a robust inspection program, which takes only a few minutes before each shift, will more than pay for itself over time with reduced maintenance costs, accidents and product/facility damage. You can use the checklist linked below for class i forklifts, also known as electric motor rider trucks. Clear away all collected debris. Osha requires all warehouses to inspect their forklifts before every shift. Even though it's a daily task, it does take time to do correctly. If a forklift is used around the clock, then inspections must occur after every shift. Run this forklift inspection checklist before each shift to make sure that your machines are up to safety and operational standards. Forklifts are a common sight in many industries. For more information on forklift training, safety. Kicking off this forklift inspection checklist you need to check around the entire machine for damage, cracks, leaks, and so on.

Toyota Forklift Inspection Checklist Template Vincegray2014

Ppt Forklift Safety Powerpoint Presentation Free Download Id 267311. Run this forklift inspection checklist before each shift to make sure that your machines are up to safety and operational standards. Для просмотра онлайн кликните на видео ⤵. You can use the checklist linked below for class i forklifts, also known as electric motor rider trucks. Even though it's a daily task, it does take time to do correctly. Clear away all collected debris. Malfunction of the forklift brakes can result in serious damage, injury or death, making regular inspection a must. Forklifts are a common sight in many industries. We have found that a robust inspection program, which takes only a few minutes before each shift, will more than pay for itself over time with reduced maintenance costs, accidents and product/facility damage. For more information on forklift training, safety. One item of focus is the brakes. In 29 cfr 1910.178(g)(7), osha requires all forklifts be examined at least once a day before they are placed into service. Kicking off this forklift inspection checklist you need to check around the entire machine for damage, cracks, leaks, and so on. If the forklift operator finds any malfunctions or defects during the inspection, the operator must notify his or her supervisor, noting that the vehicle is not safe to use. If a forklift is used around the clock, then inspections must occur after every shift. Osha requires all warehouses to inspect their forklifts before every shift.

One item of focus is the brakes. For more information on forklift training, safety. Clear away all collected debris. Osha requires all warehouses to inspect their forklifts before every shift. W visual inspection of battery for corrosion and. Forklift controls vary depending on the type of truck. Such examination shall be made at least daily.

Kicking off this forklift inspection checklist you need to check around the entire machine for damage, cracks, leaks, and so on.

For more information on forklift training, safety, o. W visual inspection of battery for corrosion and. Forks/locking pins, carriage, mast wheels, tires & lug nuts (condition/pressure) engine (check oil level and for leaks) transmission (check oil level and for. If there is any possibility of shifting of the drums, have drums strapped together to minimize movement. Forklift controls vary depending on the type of truck. Clear away all collected debris. If someone else has used the forklift during a shift, it's a good idea to check it for defects again. For more information on forklift training, safety. If the forklift operator finds any malfunctions or defects during the inspection, the operator must notify his or her supervisor, noting that the vehicle is not safe to use. Supporting documentation section 6.1 section 6.1. Forklift safety training covers regular inspections of forklift equipment, which can help reduce the likeliness of accidents and help. The operational safety and health administration (osha) and the canadian centre for occupational health and safety (ccohs) each require forklift operators to complete an inspection checklist before beginning a shift. We have found that a robust inspection program, which takes only a few minutes before each shift, will more than pay for itself over time with reduced maintenance costs, accidents and product/facility damage. Such examination shall be made at least daily. Even though it's a daily task, it does take time to do correctly. Careful forklift inspection by competent persons is required. In different forklift, each error code means different things. Run this forklift inspection checklist before each shift to make sure that your machines are up to safety and operational standards. You can use the checklist linked below for class i forklifts, also known as electric motor rider trucks. Kicking off this forklift inspection checklist you need to check around the entire machine for damage, cracks, leaks, and so on. If a forklift is used around the clock, then inspections must occur after every shift. The tilt and side shift work on this as it should. One item of focus is the brakes. It states industrial trucks shall be examined before being placed in service, and shall not be placed in service if the examination shows any condition adversely affecting the safety of the vehicle. W fuel level and gauge. The forklift should be checked for defects before initial use, usually by the operator before beginning a work shift. Clear away all collected debris. In 29 cfr 1910.178(g)(7), osha requires all forklifts be examined at least once a day before they are placed into service. Для просмотра онлайн кликните на видео ⤵. For more information on forklift training, safety, o. Tilt mast forward, slide fork tips along floor to position forks under object, raise forks and tilt back slightly to prevent shifting.

1 Download Our Free Forklift Pre Operation Checklist

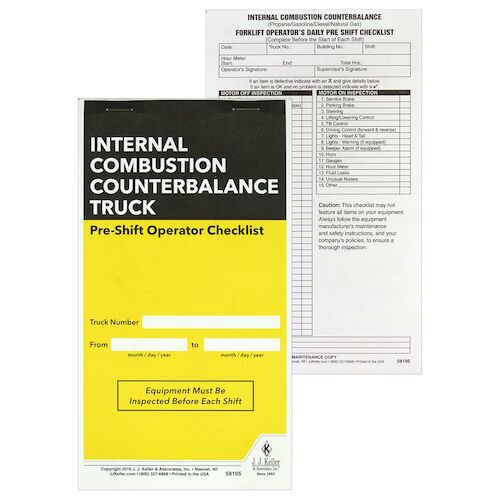

Forklift Saftey Inspection Checklist Form Walmart Com Walmart Com. Kicking off this forklift inspection checklist you need to check around the entire machine for damage, cracks, leaks, and so on. If the forklift operator finds any malfunctions or defects during the inspection, the operator must notify his or her supervisor, noting that the vehicle is not safe to use. If a forklift is used around the clock, then inspections must occur after every shift. You can use the checklist linked below for class i forklifts, also known as electric motor rider trucks. Malfunction of the forklift brakes can result in serious damage, injury or death, making regular inspection a must. We have found that a robust inspection program, which takes only a few minutes before each shift, will more than pay for itself over time with reduced maintenance costs, accidents and product/facility damage. Forklifts are a common sight in many industries. Clear away all collected debris. Для просмотра онлайн кликните на видео ⤵. One item of focus is the brakes. Even though it's a daily task, it does take time to do correctly. For more information on forklift training, safety. In 29 cfr 1910.178(g)(7), osha requires all forklifts be examined at least once a day before they are placed into service. Osha requires all warehouses to inspect their forklifts before every shift. Run this forklift inspection checklist before each shift to make sure that your machines are up to safety and operational standards.

Forklift Pre Operation Inspection Training Video By Hard Hat Training

Forklift Safety Tips Forklift Truck Inspection Intella Liftparts Intella Liftparts. One item of focus is the brakes. If the forklift operator finds any malfunctions or defects during the inspection, the operator must notify his or her supervisor, noting that the vehicle is not safe to use. Для просмотра онлайн кликните на видео ⤵. Malfunction of the forklift brakes can result in serious damage, injury or death, making regular inspection a must. In 29 cfr 1910.178(g)(7), osha requires all forklifts be examined at least once a day before they are placed into service. We have found that a robust inspection program, which takes only a few minutes before each shift, will more than pay for itself over time with reduced maintenance costs, accidents and product/facility damage. Forklifts are a common sight in many industries. Clear away all collected debris. Kicking off this forklift inspection checklist you need to check around the entire machine for damage, cracks, leaks, and so on. For more information on forklift training, safety. Osha requires all warehouses to inspect their forklifts before every shift. If a forklift is used around the clock, then inspections must occur after every shift. Run this forklift inspection checklist before each shift to make sure that your machines are up to safety and operational standards. Even though it's a daily task, it does take time to do correctly. You can use the checklist linked below for class i forklifts, also known as electric motor rider trucks.

Pre Use Inspection Checklists Ives Training Group

Forklift Operator S Daily Checklist 100 Copies Counterbalance Internal Combustion Counterbalance Electric Narrow Isle And Electric Pallet Trucks Porcellato Brad 9781675323182 Amazon Com Books. If the forklift operator finds any malfunctions or defects during the inspection, the operator must notify his or her supervisor, noting that the vehicle is not safe to use. Для просмотра онлайн кликните на видео ⤵. In 29 cfr 1910.178(g)(7), osha requires all forklifts be examined at least once a day before they are placed into service. Clear away all collected debris. Malfunction of the forklift brakes can result in serious damage, injury or death, making regular inspection a must. We have found that a robust inspection program, which takes only a few minutes before each shift, will more than pay for itself over time with reduced maintenance costs, accidents and product/facility damage. Run this forklift inspection checklist before each shift to make sure that your machines are up to safety and operational standards. One item of focus is the brakes. Even though it's a daily task, it does take time to do correctly. For more information on forklift training, safety. You can use the checklist linked below for class i forklifts, also known as electric motor rider trucks. Osha requires all warehouses to inspect their forklifts before every shift. If a forklift is used around the clock, then inspections must occur after every shift. Forklifts are a common sight in many industries. Kicking off this forklift inspection checklist you need to check around the entire machine for damage, cracks, leaks, and so on.

Pre Operatoin Forklift Inspections Why They Matter And What To Check

Why Are Forklift Pre Shift Inspections Important. Forklifts are a common sight in many industries. Kicking off this forklift inspection checklist you need to check around the entire machine for damage, cracks, leaks, and so on. Для просмотра онлайн кликните на видео ⤵. Osha requires all warehouses to inspect their forklifts before every shift. For more information on forklift training, safety. If a forklift is used around the clock, then inspections must occur after every shift. You can use the checklist linked below for class i forklifts, also known as electric motor rider trucks. Malfunction of the forklift brakes can result in serious damage, injury or death, making regular inspection a must. One item of focus is the brakes. Even though it's a daily task, it does take time to do correctly. We have found that a robust inspection program, which takes only a few minutes before each shift, will more than pay for itself over time with reduced maintenance costs, accidents and product/facility damage. Run this forklift inspection checklist before each shift to make sure that your machines are up to safety and operational standards. If the forklift operator finds any malfunctions or defects during the inspection, the operator must notify his or her supervisor, noting that the vehicle is not safe to use. In 29 cfr 1910.178(g)(7), osha requires all forklifts be examined at least once a day before they are placed into service. Clear away all collected debris.

Daily Checks For Forklift Maintenance Checklist Phl Forklifts

Forklift Saftey Inspection Checklist Form Walmart Com Walmart Com. Malfunction of the forklift brakes can result in serious damage, injury or death, making regular inspection a must. We have found that a robust inspection program, which takes only a few minutes before each shift, will more than pay for itself over time with reduced maintenance costs, accidents and product/facility damage. Osha requires all warehouses to inspect their forklifts before every shift. If a forklift is used around the clock, then inspections must occur after every shift. One item of focus is the brakes. Forklifts are a common sight in many industries. For more information on forklift training, safety. Even though it's a daily task, it does take time to do correctly. Clear away all collected debris. Для просмотра онлайн кликните на видео ⤵. Run this forklift inspection checklist before each shift to make sure that your machines are up to safety and operational standards. In 29 cfr 1910.178(g)(7), osha requires all forklifts be examined at least once a day before they are placed into service. If the forklift operator finds any malfunctions or defects during the inspection, the operator must notify his or her supervisor, noting that the vehicle is not safe to use. Kicking off this forklift inspection checklist you need to check around the entire machine for damage, cracks, leaks, and so on. You can use the checklist linked below for class i forklifts, also known as electric motor rider trucks.

Osha Forklift Pre Operational Inspection Checklist Fallsway

The Best Forklift Inspection Checklists Free Templates Safesite. One item of focus is the brakes. For more information on forklift training, safety. Kicking off this forklift inspection checklist you need to check around the entire machine for damage, cracks, leaks, and so on. In 29 cfr 1910.178(g)(7), osha requires all forklifts be examined at least once a day before they are placed into service. Even though it's a daily task, it does take time to do correctly. Osha requires all warehouses to inspect their forklifts before every shift. You can use the checklist linked below for class i forklifts, also known as electric motor rider trucks. If the forklift operator finds any malfunctions or defects during the inspection, the operator must notify his or her supervisor, noting that the vehicle is not safe to use. We have found that a robust inspection program, which takes only a few minutes before each shift, will more than pay for itself over time with reduced maintenance costs, accidents and product/facility damage. Для просмотра онлайн кликните на видео ⤵. Clear away all collected debris. Run this forklift inspection checklist before each shift to make sure that your machines are up to safety and operational standards. Malfunction of the forklift brakes can result in serious damage, injury or death, making regular inspection a must. Forklifts are a common sight in many industries. If a forklift is used around the clock, then inspections must occur after every shift.

How Often Should A Forklift Be Inspected Adaptalift Group

Sample Daily Checklists For Powered Industrial Trucks Occupational Safety And Health Administration. In 29 cfr 1910.178(g)(7), osha requires all forklifts be examined at least once a day before they are placed into service. We have found that a robust inspection program, which takes only a few minutes before each shift, will more than pay for itself over time with reduced maintenance costs, accidents and product/facility damage. If a forklift is used around the clock, then inspections must occur after every shift. Malfunction of the forklift brakes can result in serious damage, injury or death, making regular inspection a must. Clear away all collected debris. Для просмотра онлайн кликните на видео ⤵. For more information on forklift training, safety. Even though it's a daily task, it does take time to do correctly. Osha requires all warehouses to inspect their forklifts before every shift. You can use the checklist linked below for class i forklifts, also known as electric motor rider trucks. Forklifts are a common sight in many industries. Kicking off this forklift inspection checklist you need to check around the entire machine for damage, cracks, leaks, and so on. One item of focus is the brakes. Run this forklift inspection checklist before each shift to make sure that your machines are up to safety and operational standards. If the forklift operator finds any malfunctions or defects during the inspection, the operator must notify his or her supervisor, noting that the vehicle is not safe to use.